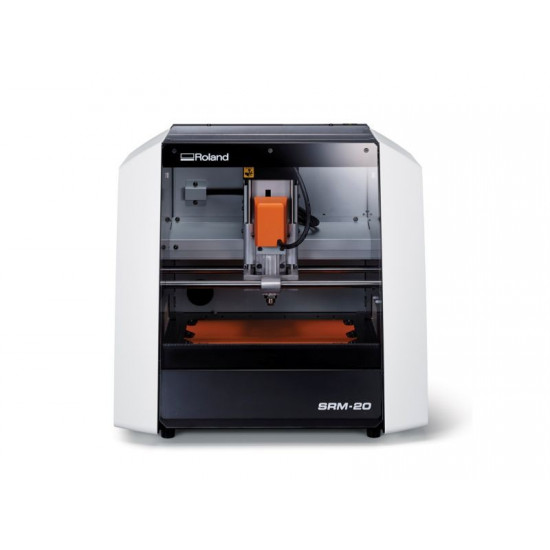

Roland SRM-20

Fine Detail and Smooth Finish

SRM-20 can bring shape to virtually any idea that springs to mind. With the SRM-20 3D milling machine, 3D data can be shaped into solid objects with exceptional precision. Capable of milling a wide range of materials, the SRM-20 is invaluable for industrial design prototypes, industrial parts, educational tools, and other applications using materials similar to the final version.

Traditional methods of rapid prototyping involve hand crafting wax, clay, and other soft materials. These methods rely on the steady hand of a craft-person and can lead to imperfections or limitations based on the choice of material.

Similarly, emerging methods of digital production, such as 3D printing, may be able to replicate an exact material, but the method can be cost-prohibitive compared to the benefit/performance ratio of the SRM-20 – lower priced technologies can yield clunky prototypes, while high performance production can dramatically increase your cost structure and use complicated software workflows.

SRM-20 uses superior motion control firmware to calibrate in 3D space. This eliminates the need for heavy, granite or steel bases to stabilize the machine.

Materials

Truly Functional Prototypes

- ABS

- POM

- Nylon Plastic Foam

- Modeling Wax

- Chemical Wood

- PVC

- Acetal

- Snap-fit parts

- Moulds for casting

- Toys and games

- Product prototypes

- Jewellery and accessories

- Furnishings and decorations

- Electrical parts and casings

- Relief signs and graphics

User Friendly and Intuitive

The SRM-20 is designed for entry level users to introduce them to the concepts of Computer Aided Manufacturing. There is no advanced Control Panel or complex adjustments necessary.

The machine has a single power button and a single milling tool. Everything else is controlled through software. the bundled VPanel software (see above) controls all essential machine function and displays all relevant machine data.

The SRM-20 reduces the time and effort of machine set-up with a complete software-controlled user interface.

The SRM-20 is designed for use in studio and educational environments. A newly improved acrylic cover protects the user from flying debris, making it perfect for offices and shools.

Additional Features

Calling All Makers!

SRM-20 has a built-in interface to allow for Arduino boards to be installed. This open architecture capability is the essence of Roland DG’s philosophy known as Monozukuri!

Install your board and program your SRM-20 to complete customized tasks for production of your favorite items.

It is a portmanteau of two japanese words –

Mono – thing

Zukuri – making of

The word Monozukuri means “Making Things”, which is the reason the SRM-20 was invented!

MonoFab is another combination word that means –

Monozukuri – Fabrication

It’s the art of making things through digital manufacturing technologies!

BUNDLED SOFTWARE

3D Product Suite

SRM-20 comes packed with features to make your journey into Computer Aided Manufacturing (CAM) easy and efficient.

This popular Industry and Education software has been updated to get the most out of your SRM-20. Milling settings can be configured in five simple steps, making operation straightforward even for those new to milling.

ClickMill Software provides direct control of the SRM-20 for surfacing, drilling holes, cutting pockets and other finishing processes, all without having to access CAD or CAM software.

The SRM-20 supports G-code NC programming language, making it well suited for both professional and educational applications.

VPanel serves as a computer-based virtual panel with all of the functionality of the physical on-board control panel, as well as tool life management and e-mail alerts. All from your PC.